- Full suite of sustainable solutions for nitrogen-based fertilizers

- Over 75 years of licensing and engineering experience

- Energy-efficient loops and low-emission designs

- Strong integration with ammonia and nitrate platforms

Urea is the most widely used nitrogen fertilizer in the world, supporting global agriculture and food production. Its high nitrogen content, low cost, and ease of storage and transport make it the fertilizer of choice in both developed and emerging markets.

However, urea production is energy- and emissions-intensive, relying heavily on natural gas and steam. As decarbonization targets intensify across the fertilizer industry, producers face a growing challenge: how to keep their plants competitive and compliant, while reducing environmental impact and unlocking new value streams.

Industrial Applications of Urea

Although urea is best known for its role in agriculture, its industrial applications are increasingly important. Urea serves as a key intermediate in:

- Diesel Exhaust Fluid (DEF / AdBlue®) for NOₓ reduction in transport

- Melamine and resins for the plastics and coatings industries

- UAN (Urea Ammonium Nitrate) solutions for precision liquid fertilizers

- Adhesives and specialty chemicals

Nextchem Technologies For Urea

Although urea is best known for its role in agriculture, its industrial applications are increasingly important. Urea serves as a key intermediate in:

- Diesel Exhaust Fluid (DEF / AdBlue®) for NOₓ reduction in transport

- Melamine and resins for the plastics and coatings industries

- UAN (Urea Ammonium Nitrate) solutions for precision liquid fertilizers

- Adhesives and specialty chemicals

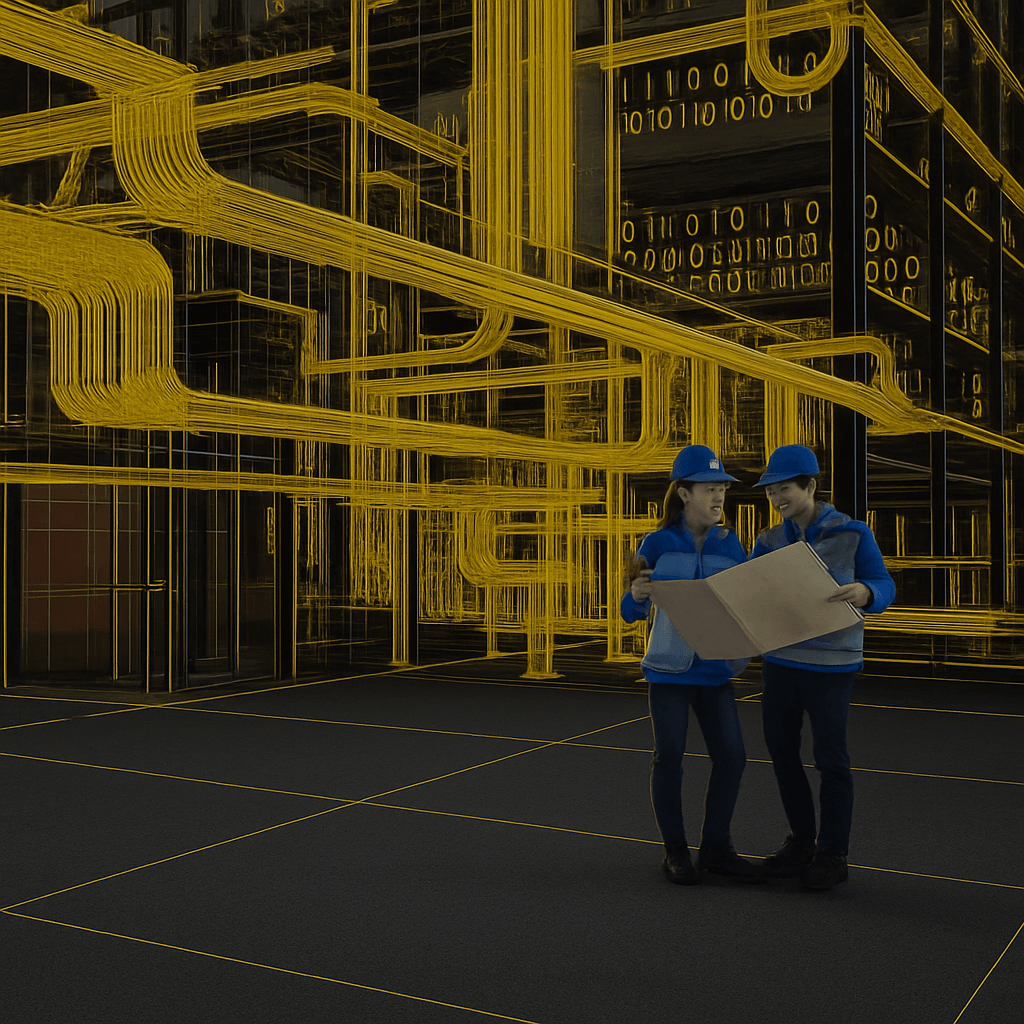

Whether you are conceptualizing a new plant, optimizing an existing one, or planning a renovation, we provide end-to-end support throughout your plant’s entire lifecycle. Learn more about our service lines and innovative urea solutions:

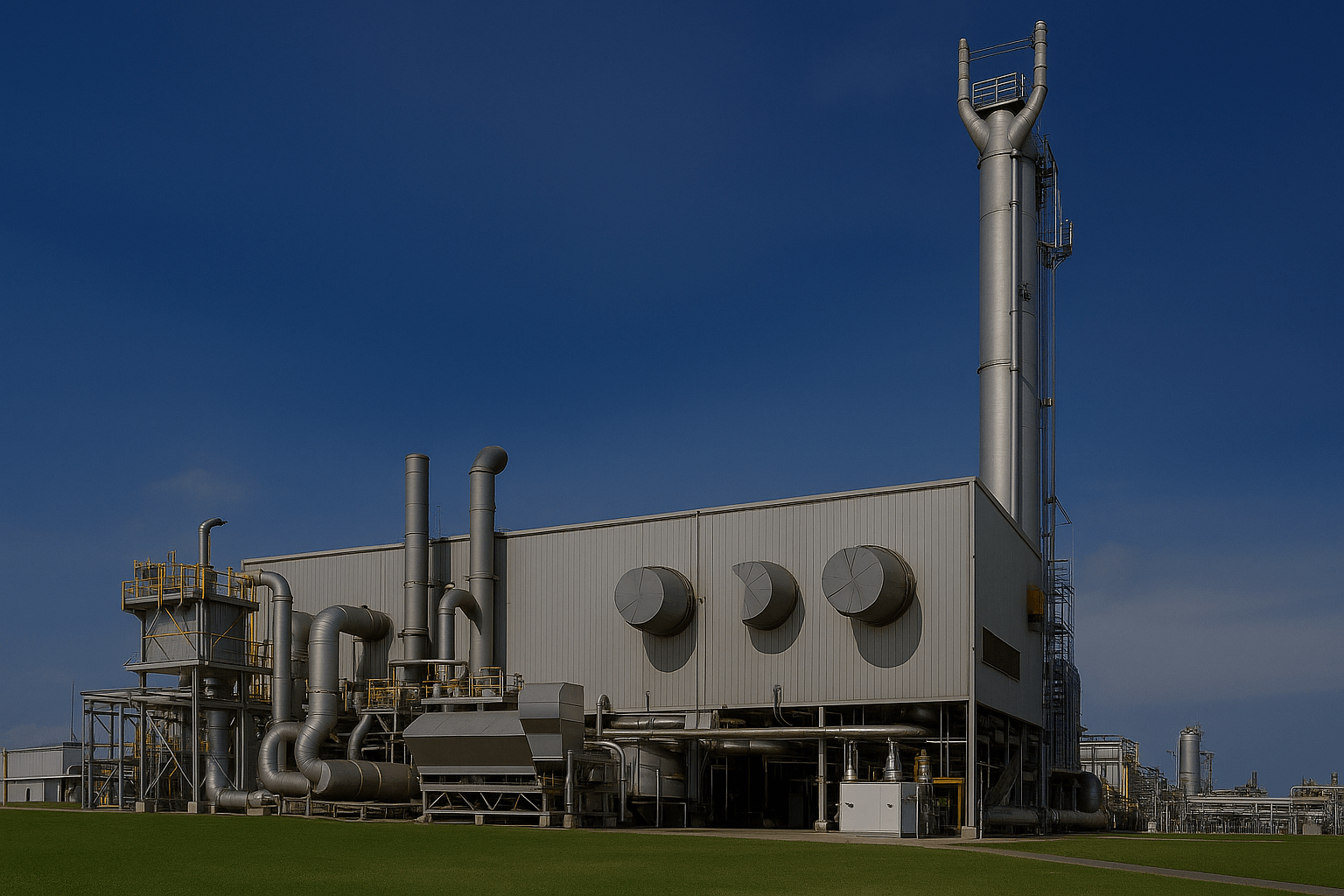

Stamicarbon, the nitrogen technology licensor of NEXTCHEM, has delivered numerous projects worldwide covering technology licensing, plant optimization and revamping for urea, ammonia, and nitric acid production.

Nextchem provides:

- Plant assessment

- Feasibility studies

- Technology licensing

- Proprietary Equipment

- Revamps and plant debottlenecking

- Full Life Cycle Support