NX PTU™

Our technology for second generation lipids pre-treatment, a reliable and flexible solution for multiple feedstock.Advanced Technology for SAF and RD Production

- Proven and well-known technology developed from oleochemical industry.

- Full compatibility with all licensed HEFA units.

- Pre-treatment yield up to 99% with minimal oil losses.

- High flexibility to a wide spectrum of different feedstock.

- No use of bleaching earths, no solid waste disposal, and minimal water consumption.

- Pilot pre-treatment unit available to validate customer samples.

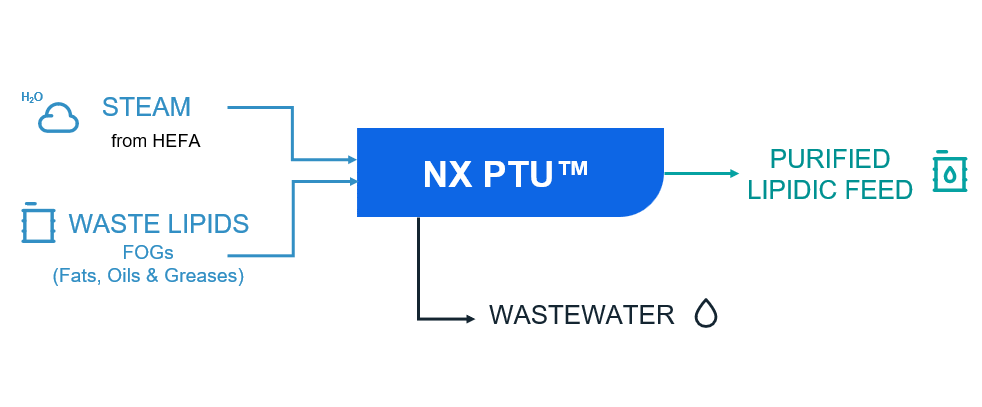

NX PTU™ is an innovative solution developed to respond to the growing need of processing different and increasingly contaminated feedstocks.

In the broad push for the biofuel consumption, like Sustainable Aviation Fuel (SAF) and Renewable Diesel (RD, also known as HVO), the proper pre-treatment is essential to remove the contaminants and impurities in the feedstock (waste oils and fats) suitable for the HEFA process.

The technology has been successfully tested with Used Cooking Oil (UCO), Palm Oil Mill Effluent (POME), Animal Fats (Tallow), and others, reaching the outlet target values usually required by HEFA catalyst of:

- Total metals < 10ppm

- Phosphorus < 3ppm

NX PTU™ does not use bleaching earths providing higher yields and lower OPEX, avoiding the production of solid effluents.

NEXTCHEM can offer NX PTU™ combined with NX SAF™ BIO for the production of SAF and RD or as stand alone technology.

Key Benefits of NX PTU™

- Pre-treatment yield up to 99% with minimal oil losses.

- High flexibility to a wide spectrum of different feedstock.

- Low OPEX: no use of bleaching earths, no solid waste disposal, and minimal water consumption.

- Easy integration with HEFA: heat consumption for evaporation can be provided by HEFA process.

- Test your specific feedstock: pilot pre-treatment unit available to validate customer samples.

Where NX PTU™ Fits in

NX PTU™ is capable of processing the following raw materials:

- Used Cooking Oil (UCO),

- Distillers’ Corn Oil (DCO),

- Palm oil residue and by-products (POME, SBEO, PFAD)

- Animal Fats (Tallow),

- Other feedstocks can be evaluated, with dedicated test campaign.

Target sectors:

- Feedstock collectors,

- Biorefineries,

- HEFA technology providers.

Technical Overview

The process removes contaminants and impurities with low oil losses and low operating expenses.

To do so, the following steps are included:

- Clarification unit

- Weak acid degumming

- Strong acid reaction

- Water washing and hydrolysis

Water recovery section allows to minimize the overall water consumption and waste water treatment costs.

ABOUT NEXTCHEM

NEXTCHEM is MAIRE’s company dedicated to Sustainable Technology Solutions. Leveraging our deep expertise in nitrogen, hydrogen, carbon capture, fuels, chemicals, and polymers, we deliver groundbreaking solutions and processes that fully enable the energy transition.

Building on the rich legacy of our group for over 70 years, we are dedicated to developing and offering technology solutions, processes, basic engineering designs, as wellas proprietary equipment and catalysts, to drive global decarbonization efforts forward.

Whether you're planning a new hydrogen facility, upgrading an existing plant, or seeking low-carbon alternatives, Nextchem provides:

- Technology licensing

- Process design packages (PDP)

- Proprietary equipment

- Digital solutions

- Post-PDP services

Download the leaflet to discover all the key feature about our tecnology.