NITRATES

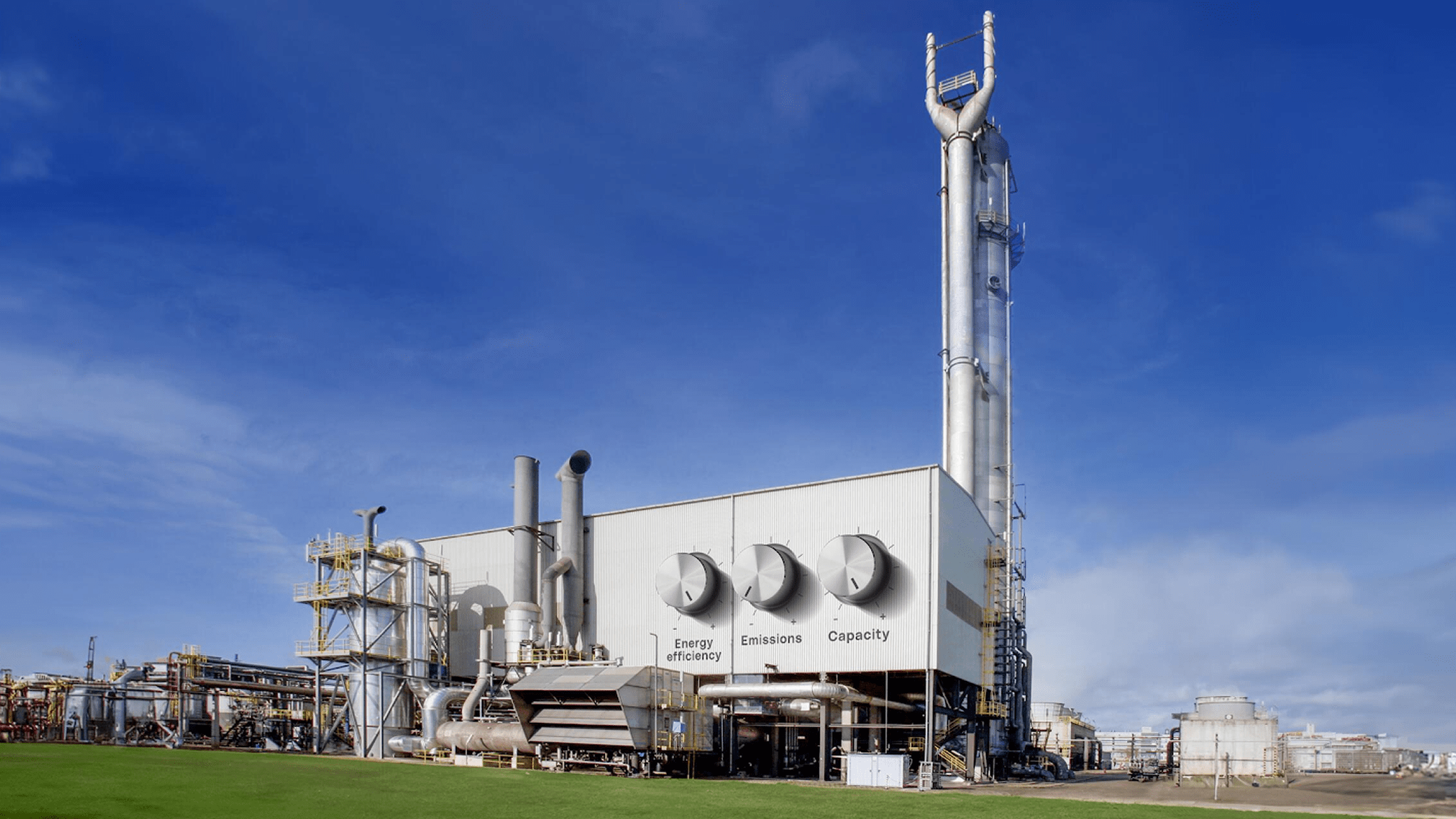

Efficient, safe, and low-emission nitric acid production for fertilizers and beyond

Why Nitrates Matter

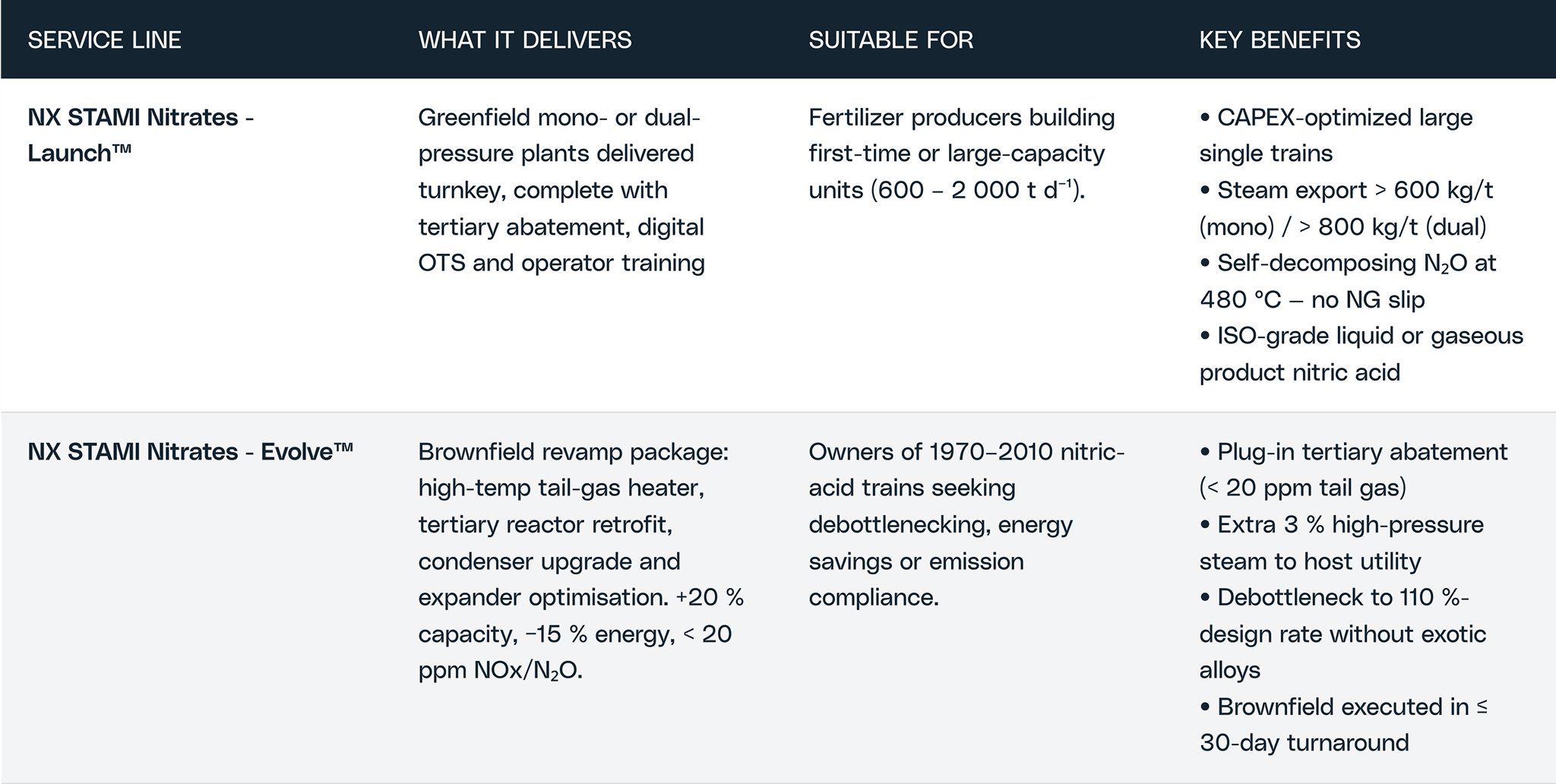

- Greenfield: 600 → 2000 t/d single-train capacity

- Revamp: +20% output, −15% energy, < 20 ppm N₂O/NOx

- Steam export up to 800 kg/t at 45 bar, 450°C

- Corrosion-free design—30 yr references, no exotic alloys

- Full lifecycle support

Nitric acid is a cornerstone of the global fertilizer industry, with over 80% of production used to create ammonium nitrate and UAN (urea ammonium nitrate). It is also a critical intermediate for producing explosives, specialty chemicals, and advanced fuel components.

The challenge for producers today lies in building or revamping plants that meet stringent environmental regulations, optimize energy recovery, and reduce both emissions and total cost of ownership, all while maintaining operational safety and reliability.

Industrial Applications of Nitric Acid

Nitric acid serves both agriculture and industry as a vital input for:

Nextchem Technologies for Nitric Acid

Through Stamicarbon, NEXTCHEM provides NX Stami™ Nitrates, a reliable and high-efficiency technology for both mono-pressure and dual-pressure nitric acid production.

Mono- and dual-pressure nitric-acid flowsheet with maximum energy recovery

Stamicarbon, the nitrogen technology licensor of NEXTCHEM, has delivered numerous projects worldwide covering technology licensing, plant optimization and revamping for urea, ammonia, and nitric acid production.

Nextchem provides:

- Plant assessment

- Feasibility studies

- Technology licensing

- Proprietary Equipment

- Revamps and plant debottlenecking

- Full Life Cycle Support

Download the leaflet to discover all the key feature about our tecnology.

FAQ

How can I ensure that my nitric acid plant complies with NOx and N2O emission standards?

A reliable and advanced solution is adding a tertiary abatement system to drive more efficient and more sustainable nitric acid production. It features a high-temperature reactor with an Fe-zeolite catalyst. This single unit efficiently removes both NOx and N2O, ensuring your plant meets the most stringent environmental regulations. Stamicarbon Nitric Acid design allows you to use a tertiary abatement system, ensuring your plant complies with global standards.

Can I integrate Nitric Acid production into other fertilizer production lines?

Yes, the nitric acid plant can be offered as an integrated solution within a larger complex for UAN (Urea Ammonium Nitrate) production, combining the nitric acid plant with urea solution, ammonium nitrate solution, and UAN mixing plants.

How can I reduce energy consumption in my nitric acid plant?

NX Stami™ Nitrates technology is designed for maximum energy recovery, primarily through the unique positioning of the third tail gas heater. This results in the lowest energy consumption and higher steam exports, significantly reducing your plant's operational expenditure (OPEX).